Rigid-Flex PCB

Rigid-flex PCB is a type of circuit boards that combines both

Rigid and flexible board technologies into a single board.

Andwin provide fast turn Rigid-flex pcb manfucturing,

Rigid-flex pcb prototype & volume production fabrication.

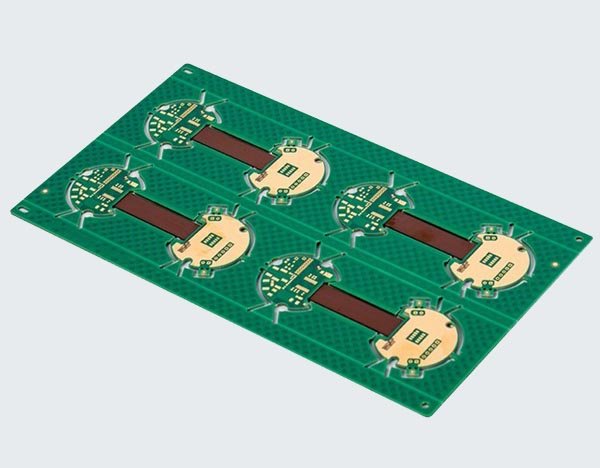

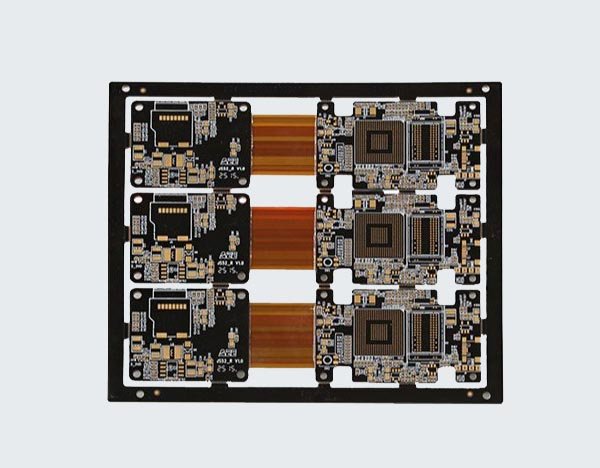

Rigid-Flex PCB products

Andwin FPC could make Rigid-flex pcbs, Multilayer Rigid-Flex boards etc.

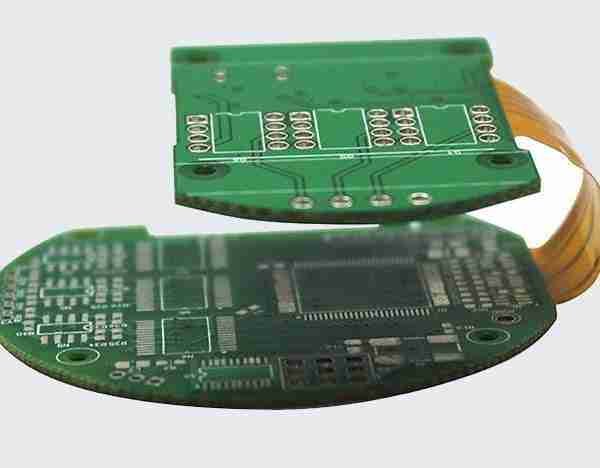

Rigid flex PCBs consists of multiple layers of flexible circuit substrates that are laminated together with layers of rigid circuit boards.

Rigid-flex PCBs are used in applications where space is limited and the board needs to be able to bend or flex without breaking.

Rigid-Flex circuit boards are composed of a combination of rigid and flexible circuit boards that are permanently connected to another.

Rigid-Flex PCBs Technical and Production Process

Whether producing a rigid flex prototype or production quantities requiring large scale Rigid-Flex PCBs fabrication,

Andwin PCB technology is well proven and reliable.

All the flexible components of the Rigid-Flex assembly have completely different handling, etching, and soldering processes than rigid FR4 boards.

Careful consideration of Rigid-Flex solutions and assessment of the available options at the early stages in the rigid-flex PCB design phase will return significant benefits.

The Rigid-Flex PCBs fabricator must be involved early in the design process to ensure the design and fab portions are both in coordination and to account for final product variations.The Rigid-flex PCB is particularly good in overcoming space and weight issues with spatial degrees of freedom.

The Rigid-Flex manufacturing phase is also more complex and time-consuming than rigid board fabrication.

It is much more effective than creating hardware or components of the orthodox designs.

For better portability of a device, the conventional boards can be problematic which is fixed by flexible PCB.

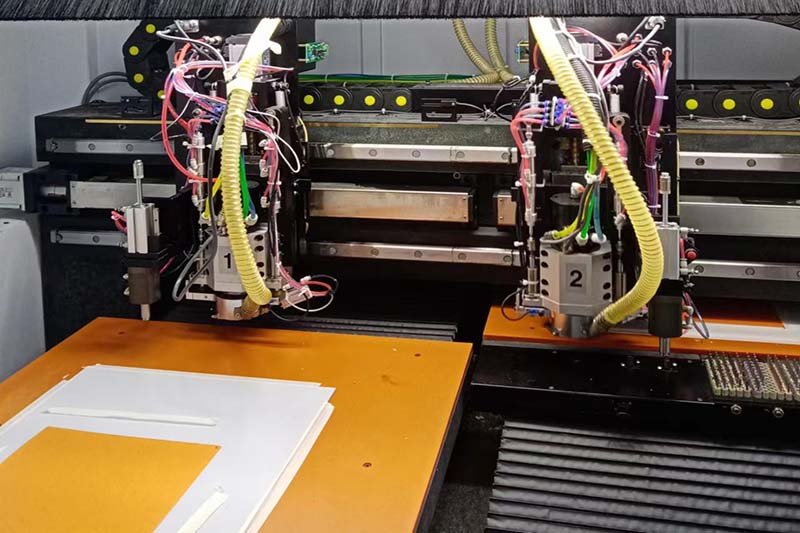

Rigid-Flex PCB production Equipments

Rigid-Flex PCBs Fabrication Applications

The basic applications of Rigid flexible PCBs are static and dynamic which is confirmed by the manufacturers before it starts designing. A better understanding of these applications enhances the choice according to the materials and components used in creating the PCB.

Static Application: The applications where the flex circuit is installed as flex-to-fit. In these applications, the circuits are designed with minimal flex and used in the inexpensive Electro Deposited (ED) copper.

Dynamic Application: The applications involved in the circuit being flexed multiple times to ensure better performance of the application. The flexible PCBs are designed with Rolled Annealed (RA) copper for these applications.

Computer Electronics: Computer electronics tend to be small and thin that may reach high temperatures sometimes. According to the computer specifications, it highly relies upon the flexible PCBs for better operation. The hard drive components should be flexible enough to sustain the maximum speed for data writing and other tasks that are comparatively small and thin. Longer operating time makes the hard drives turn to hot which also requires having another board with the ability to withstand high temperatures. In the hard drives, these are often credited by enabling a long-lasting solution. Not only in the computer the flexible PCBs are also working great for other consumer electronics like televisions, gaming systems, printers, and microwaves.

Automotive Electronics: The majority of the electronic hardware utilizes the advantages of flexible PCBs in modern automobiles including engine management units, anti-lock braking systems, airbag controllers, instrument panels, dash systems, and so on. These PCBs are deliberate to fit into lesser spaces and irregular shapes give enough flexibility to the engineers. It syncs with other electronics without the need for heavy cable setups or connectors. It is also important to cope with the extreme conditions in cars. The PCBs can be out in intense heat or cold or may experience extreme vibration while driving. In some vehicles, weight management is also necessary. Even a small input can make a huge difference. From all these perspectives flexible boards are perfect as lightweight and small size attributes.

Smartphones and Gadgets: Smartphones and other compact gadgets are the top candidates for flexible PCBs. For easy carry and better portability, this needs to remain small, lightweight, and portable. To make the connection and synchronization with all the core components single and thin-layer boards are needed. As the mobile devices take a trip in tremendous heat and cold environment so endurance is important for the adaptation by the changing temperatures and environments. Technological advancement has started to come with flexible screens that can bend and roll up and flexible PCB is the must-have. It is also necessary to make certain that the water-resistance and waterproof repelling characteristic facilitates the phones so that it can work while and after it is connected with anything liquid.

Healthcare Applications: The flexible PCBs are the key for the pharmaceutical, medical, and healthcare facilities especially for the applications where the circuits require enduring in intense conditions inside the human body. For example, the PillCam needs the super-fine flex circuitry with the assurance of complying with non-toxic and durable add-ons. Such exceptionally tiny and changeable applications permit medical experts to get an exact view of the ailments from the inside of the body. Even the realistic prosthetic limbs also need to have flexible and organic material since it will be implanted on the body. The researchers developed it by processing printed circuitry allowing it to move naturally without making any damage or side-effects.

Aerospace Applications: The Heads-Up-Displays are used in aerospace. It is a well-known technology for the display of operational data directly in the pilot’s field of vision. This improves the requirement to look away from an impending goal to interpret significant operational data in a flight. The latest additions of HUD apply the wearable technology as long as remote 3D holographic images in a flip-down visor mounted onto the helmet. For a high-resolution 3D imaging flexible PCB is important to drive the waveguide optical system. It uses the HoloEve’s liquid crystal for a clear display. The flexibility, reliability, and performance of the PCB cables make it effective in real-time visualization. Moreover, the lightweight compatibility increases its feasibility to mount the display directly on the pilot’s helmet instead of the aircraft.

Rigid-flexible PCBs are mostly used for its extended reliability and maximum adaptability.

When the circuit needs to be curved for a package assembly, the flexible PCB is crucial.

For flexing and warping, this PCB is ideal because of its compact and limiting situations.

The demand has increased at unprecedented levels and the growth will be much more than this in the coming annual periods.

A few of our customers